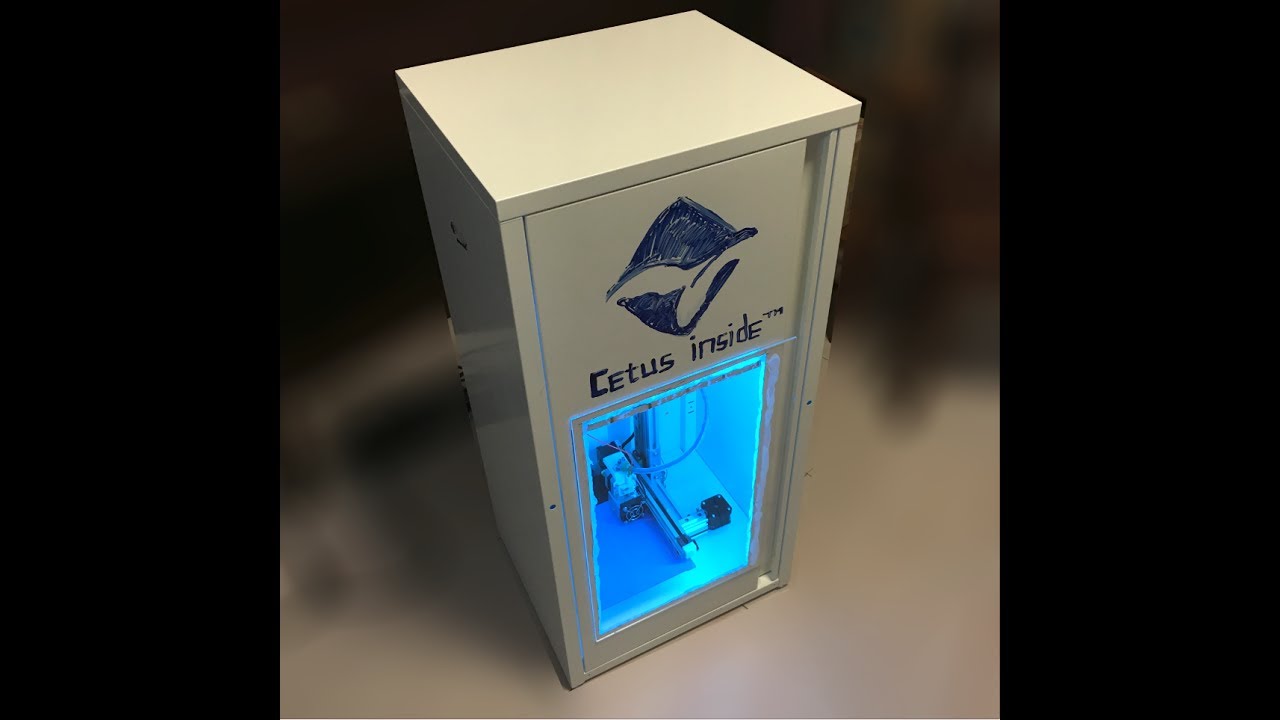

Upon startup of your printer the sensor will light up and do a self test.

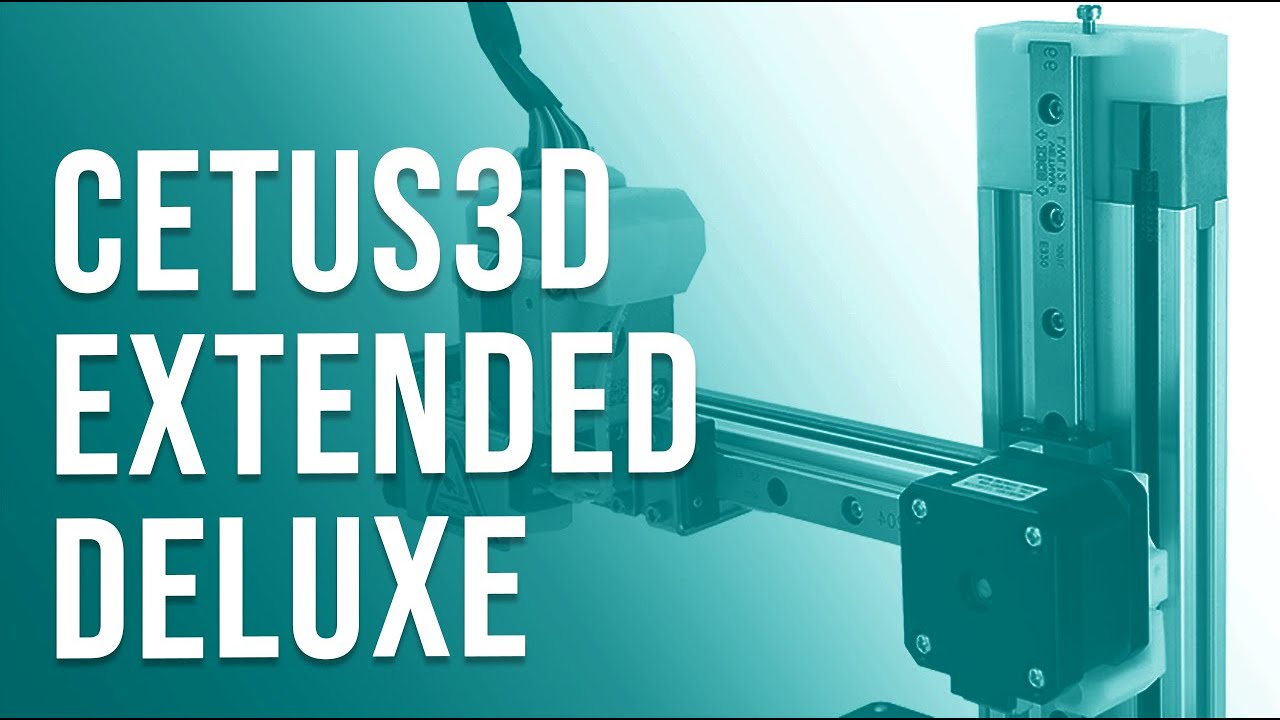

Now that we have the sensor mounted and hooked up to the door connector and the modified auxiliary port on the extruder board we can test if everything is working. The end result should look something like this: Calibration G-Code You will need 2 10mm M3 bolts to mount it on the extruder assembly and 2 10mm M3 to mount the sensor to the bracket. I printed this using 0.1 layer height and 0.2 mm nozzle. To mount the 3D Touch sensor to the extruder assembly I designed a bracket. Most of these settings are already in the confix.txt file, you will need to modify and uncomment based on the above settings Bracket That determine what pin is connected to the switch. The second part is are the leveling settings: Make sure that there is no other reference in your confiuration file to pin 1.18 _pin 1.18 # Pin connected to the aux-port

Modify the following lines in your config.txt file: First the servo, this controls the up and down movement of the pin. There are three things that need to be setup in the config.txt file. Putting everything together and connecting the actuator to the extruder board it looks like this. Signal (connected to 5V with 10k resistor).The pins on the left are from top to bottom: This is how I eventually modified my extruder board to get the right connections to the auxiliary connector.

By reverse logic setting it to 97% got me a 3% duty cycle and I could trigger the actuator. The only minor issue was that setting the pin to 3% resulted in a 97% duty cycle. Now I got the right signal between GND and the Signal pen. TinyFab suggested using a 10k resistor between 5V and the signal. This meant that I needed something to make the signal go high against the GND pin. As can be seen, by the diagram, there is a transistor attached to pin 1.18 that pulls the signal low on a high from a pin. I hoped life would be easy and I could just connect the three pins to the auxiliary connector on the extruder. Then came the next challenge connecting the actuator. So I started with the easy stuff solder a socket to the mainboard for the door check like so Port 2.13 - This is attached to the door check on the mainboard.Port 1.18 - This is connected to the second header on the extruder board.The actuator is triggered by a PWM signal on the three pin connector where the duty cycle determines the functionsīased on the image show earlier we have two port on the tinyFab CPU that we can use

0 kommentar(er)

0 kommentar(er)